Before you read this, know this this is for someone who wants to split the crankcase without dissasembling the entire engine. Example: A cracked kickstart shaft journal that is laying around and bouncing in the block, but the engine runs fine.

If i miss anything or provide false information, feel free to PM me and explain your point, i will gladly fix any mistakes.

TOOLS

To tackle this you will first need to gather your tools. You will need (1) 1/4 inch or 3/8 inch socket wrench (I suggest 3/8, it’s bigger and easier to break loose the tough bolts), metric sockets (deep well works best), (1) extension, allen wrenches, a sharpie and baggies, and a (2) flathead screwdrivers. Make sure they're thick enough to take some strain.

*When trying to remove really grimy and rusty bolts, ALWAYS use a 6-pt socket - less likely to round off your bolts.

DRAIN THE OIL FIRST. Common sense.After that is done, you will need to remove the side covers. Bag and Tag the bolts, makings sure to seperate what bolts are for what side.

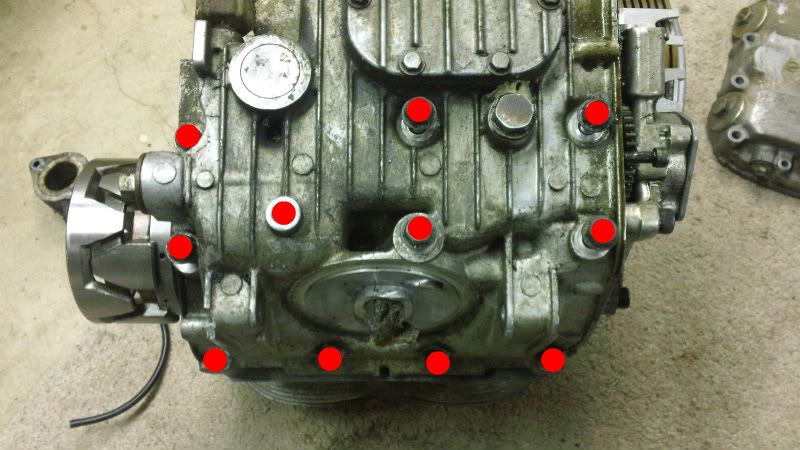

After that is done, remove the chain tensioner for the starter and slide the cog off of the spline. Bag and tag the chain, tensioner and cog in one bag. Go to the top and remove your starter cover (marked blue in the picture), and as always, B&T the cover and bolts in with the chain. Then remove the bolts holding the cases together (these are marked in red) and B&T them labeled TOP OF CASE, or something similar.

Now to remove the starter, take out the bolts holding the starter to the block, not the screws. B&T the bolts with the rest of the starter stuff and wiggle out the starter. I took a piece of wood and lightly tapped it with a hammer while it was pressed against the spline on the starter. That worked pretty well.

There will be 3 bolts under the starter that need to be removed in order to crack the case open, if you forget these three and start to bust open your case after everything else is out, nothing happens. Again, ask me how I know. The ones in red need to be removed and the blue are the holes where the starter bolts went in.

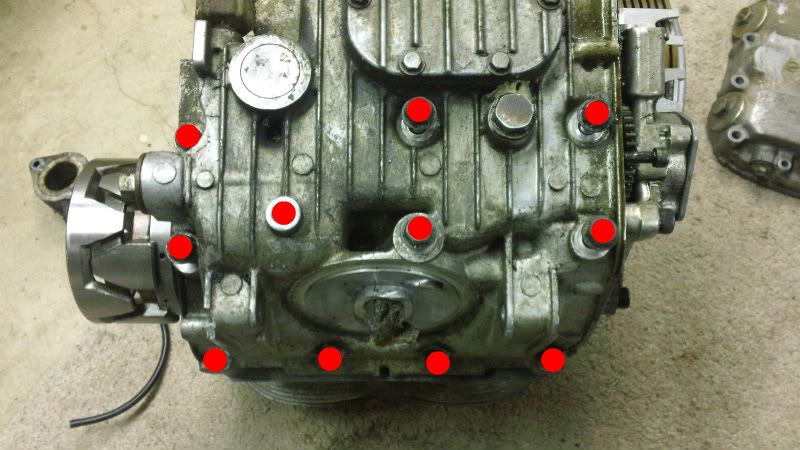

Now flip the engine and remove all the bolts that are red and don’t forget to B&T.

After all of your bolts are out, make sure you didn’t forget any and put a block of wood next on the place I’m pointing out with my long screwdriver, and start tapping it with a hammer, gradually hitting it harder until it starts to give. DO NOT WAIL ON IT.

When it starts to come up, shove a screwdriver or something under there, NOT FAR, just enough to wiggle and keep it up while you move to the other side.

find this place on right hand side of the engine the start repeating the process.

Put a screw driver in that slot and just move them up and down. At the same time so it rocks the bottom of the case, which is now the top, until you can take it off. BEHOLD!!! You now have a split case!

once again, feel free to PM me and point out any flaws. hope this helps someone.

Thanks to travis for the editing and drewpy for the criticisim.

If i miss anything or provide false information, feel free to PM me and explain your point, i will gladly fix any mistakes.

TOOLS

To tackle this you will first need to gather your tools. You will need (1) 1/4 inch or 3/8 inch socket wrench (I suggest 3/8, it’s bigger and easier to break loose the tough bolts), metric sockets (deep well works best), (1) extension, allen wrenches, a sharpie and baggies, and a (2) flathead screwdrivers. Make sure they're thick enough to take some strain.

*When trying to remove really grimy and rusty bolts, ALWAYS use a 6-pt socket - less likely to round off your bolts.

DRAIN THE OIL FIRST. Common sense.After that is done, you will need to remove the side covers. Bag and Tag the bolts, makings sure to seperate what bolts are for what side.

After that is done, remove the chain tensioner for the starter and slide the cog off of the spline. Bag and tag the chain, tensioner and cog in one bag. Go to the top and remove your starter cover (marked blue in the picture), and as always, B&T the cover and bolts in with the chain. Then remove the bolts holding the cases together (these are marked in red) and B&T them labeled TOP OF CASE, or something similar.

Now to remove the starter, take out the bolts holding the starter to the block, not the screws. B&T the bolts with the rest of the starter stuff and wiggle out the starter. I took a piece of wood and lightly tapped it with a hammer while it was pressed against the spline on the starter. That worked pretty well.

There will be 3 bolts under the starter that need to be removed in order to crack the case open, if you forget these three and start to bust open your case after everything else is out, nothing happens. Again, ask me how I know. The ones in red need to be removed and the blue are the holes where the starter bolts went in.

Now flip the engine and remove all the bolts that are red and don’t forget to B&T.

After all of your bolts are out, make sure you didn’t forget any and put a block of wood next on the place I’m pointing out with my long screwdriver, and start tapping it with a hammer, gradually hitting it harder until it starts to give. DO NOT WAIL ON IT.

When it starts to come up, shove a screwdriver or something under there, NOT FAR, just enough to wiggle and keep it up while you move to the other side.

find this place on right hand side of the engine the start repeating the process.

Put a screw driver in that slot and just move them up and down. At the same time so it rocks the bottom of the case, which is now the top, until you can take it off. BEHOLD!!! You now have a split case!

once again, feel free to PM me and point out any flaws. hope this helps someone.

Thanks to travis for the editing and drewpy for the criticisim.

Last edited: