hdscarbro

David

I started this build a while back and won't repost everything that I've done. Here's a blog you can peruse if you want to go back to the beginning of the project. Going forward, I'll try to post updates here as they happen. Comments and suggestions are greatly appreciated.

Here's the bike I started with. It was a $100 non-runner sold to me by a guy the empties junk out of houses for sale. The Suzuki tank was a thrown in with the purchase.

Here's a current photo.

Here's my current plan:

1) Get all of the electrical bits connected and working: headlight, signaled, taillight, etc.

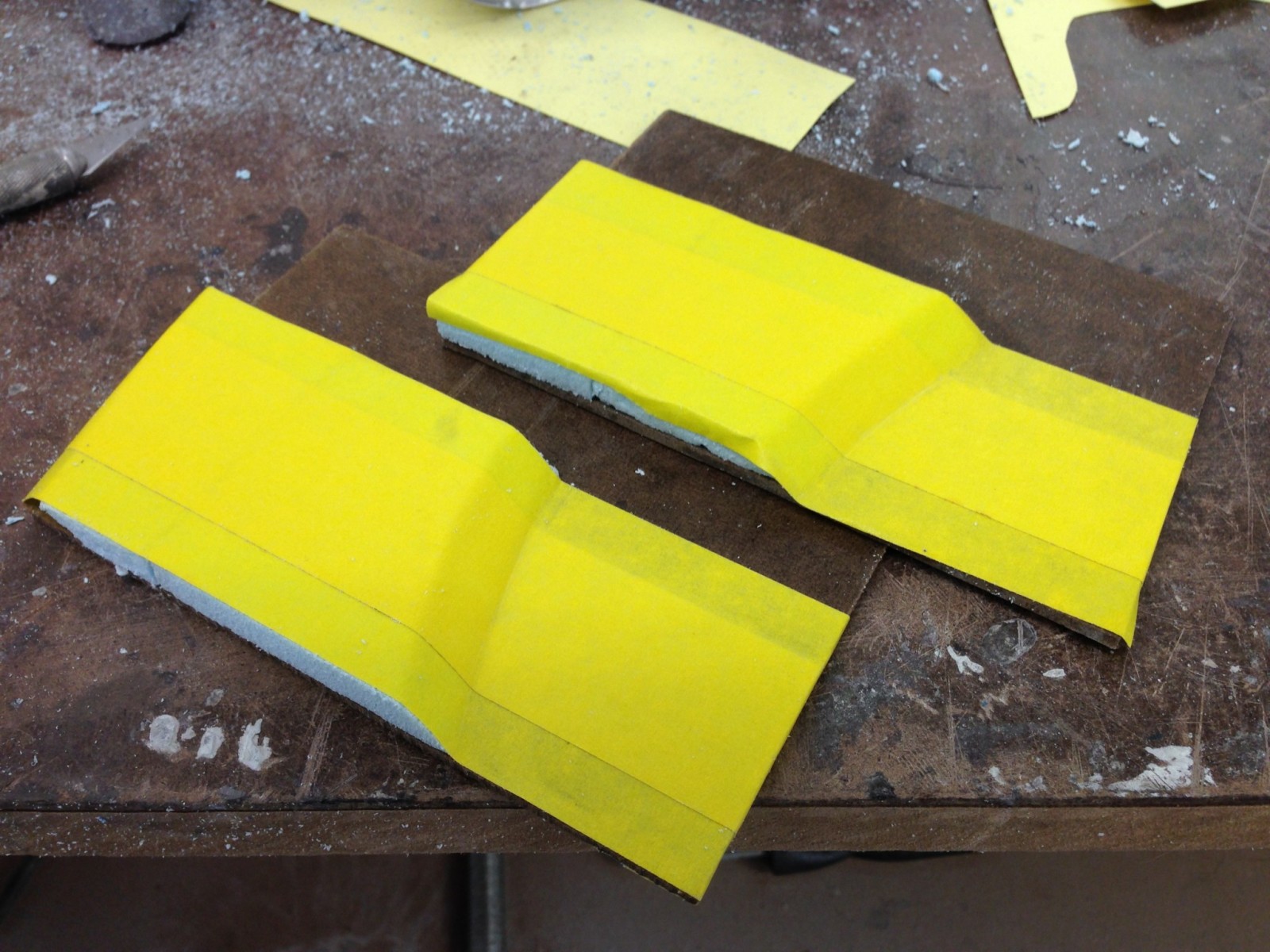

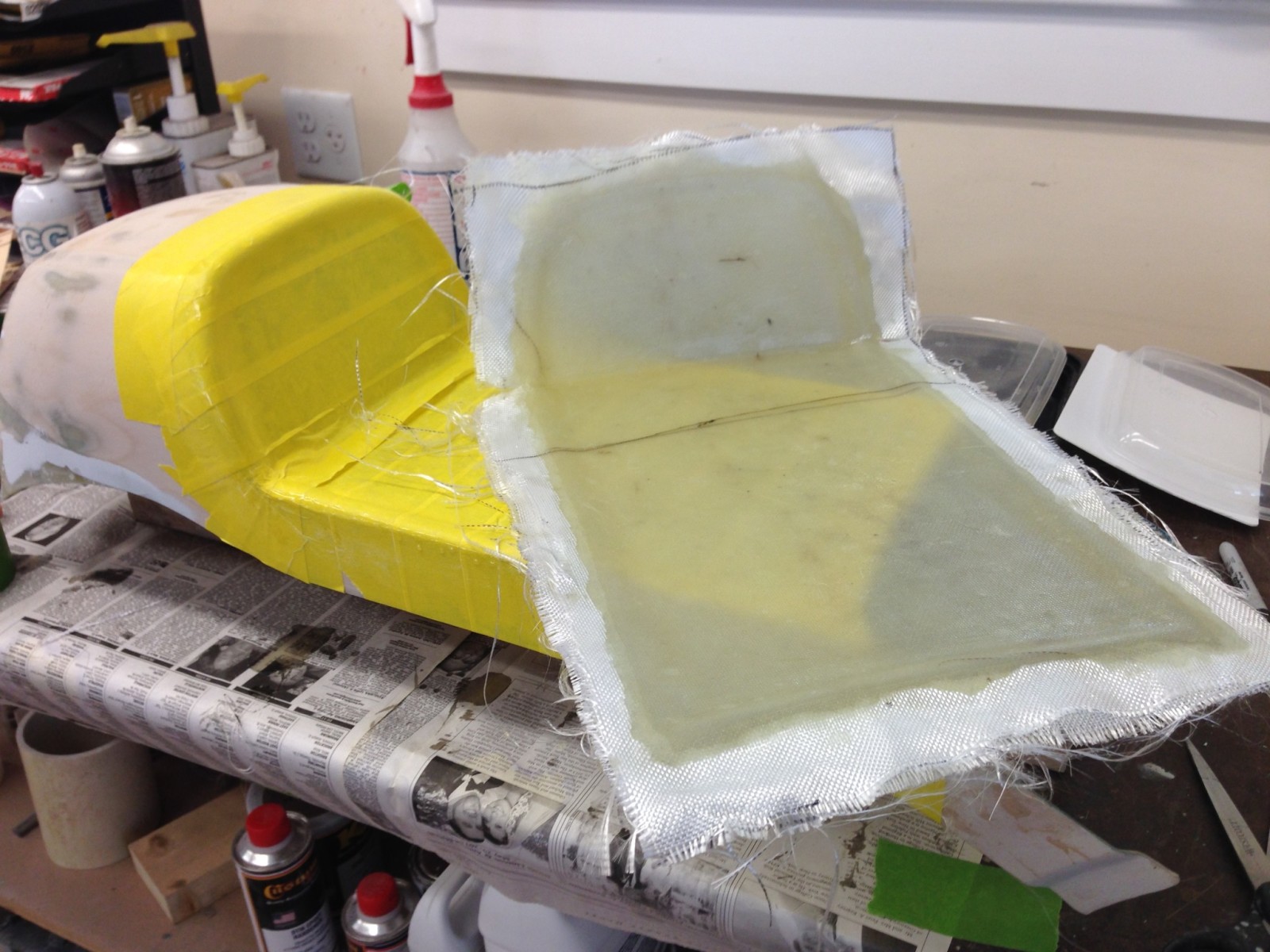

2) Finish the fiberglass seat and fender, prep for paint and get a seat made.

3) Footpegs, rear brake and shifter. Planning to rework the existing pegs to move them back an inch or two.

Here's the bike I started with. It was a $100 non-runner sold to me by a guy the empties junk out of houses for sale. The Suzuki tank was a thrown in with the purchase.

Here's a current photo.

Here's my current plan:

1) Get all of the electrical bits connected and working: headlight, signaled, taillight, etc.

2) Finish the fiberglass seat and fender, prep for paint and get a seat made.

3) Footpegs, rear brake and shifter. Planning to rework the existing pegs to move them back an inch or two.