iamunique127

XS360C Owner

How does your master cylinder sit with those drag bars? Mine would roll forward enough before the banjo bolt hit the fork. Is it a stock unit?

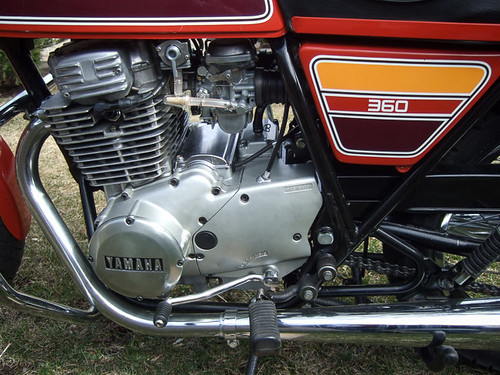

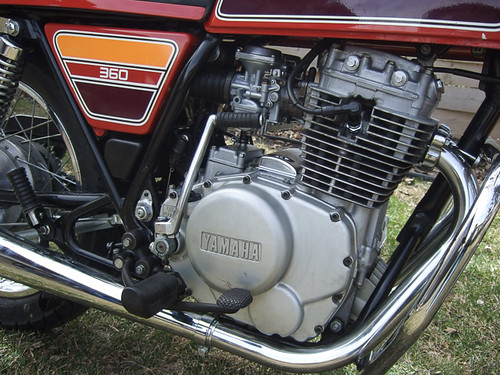

Hey jthiessen, after a bit of dicking around I got the brake hose routed for the flat bars. I guess I can always file the housing like the other guy did but I decided to try using a 90º banjo and routing the hose to the left side of the ignition switch and then straight into the master cylinder, like so:

The MC isn't so far from level as it looks. Here's a bit of a better view of the banjo

I had the brake hose made up with adapters to accommodate the Russel fittings. It is a stock master cylinder. Hope that helps.