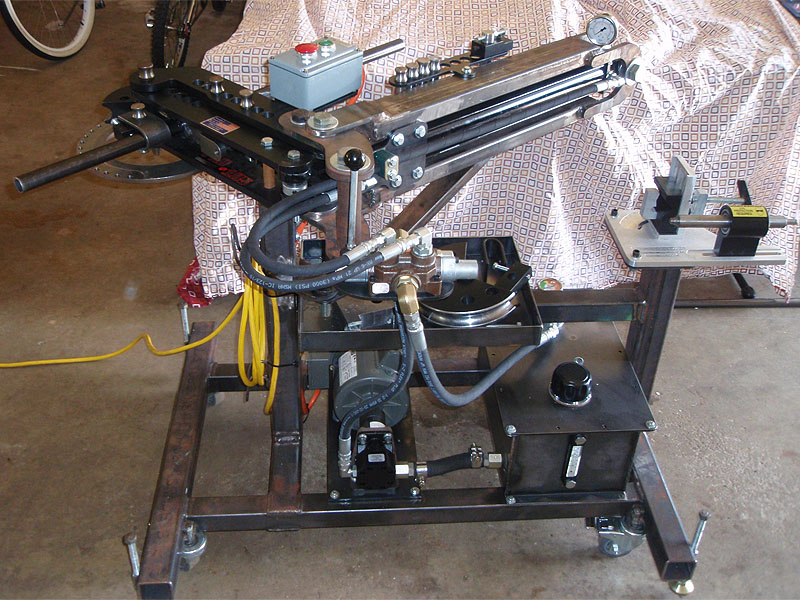

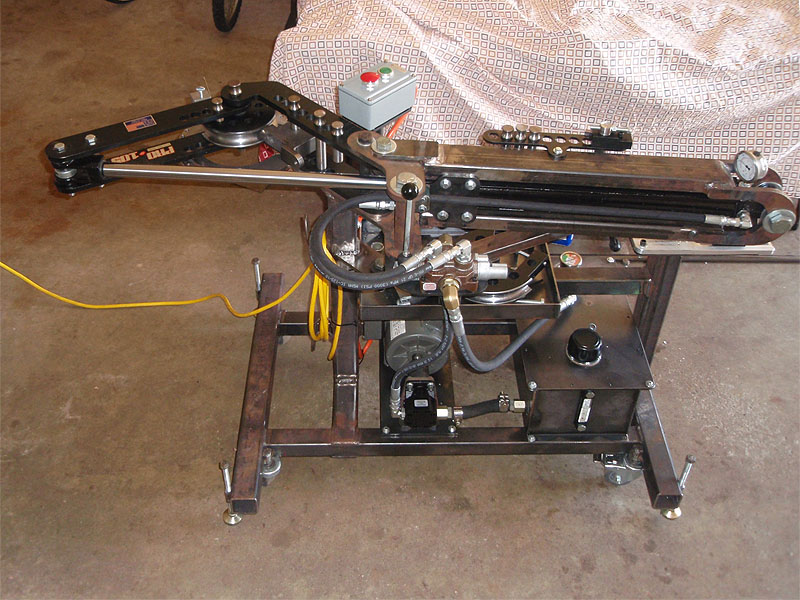

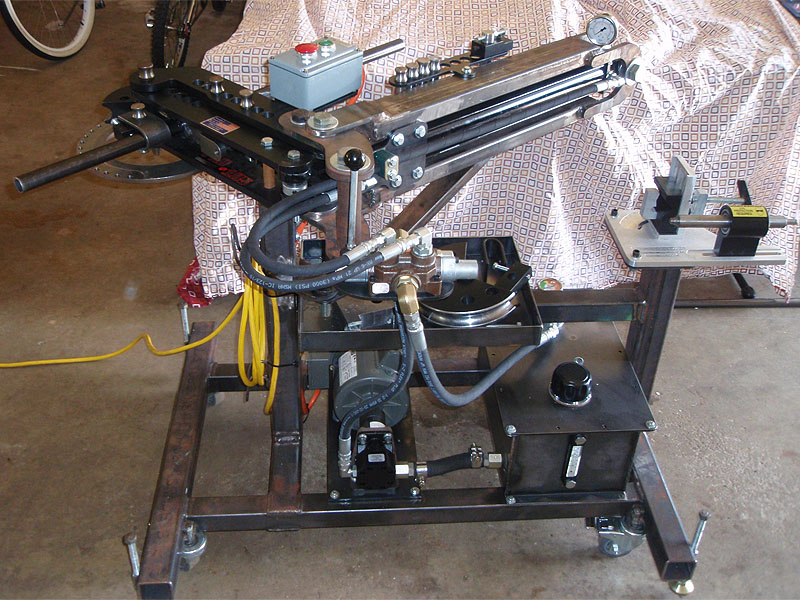

I posted this over on XS650.com but thought I'd share here too. Here's the thread over there: http://www.xs650.com/forum/showthread.php?t=13198. This is what I've been using to make the universal hardtail kits.

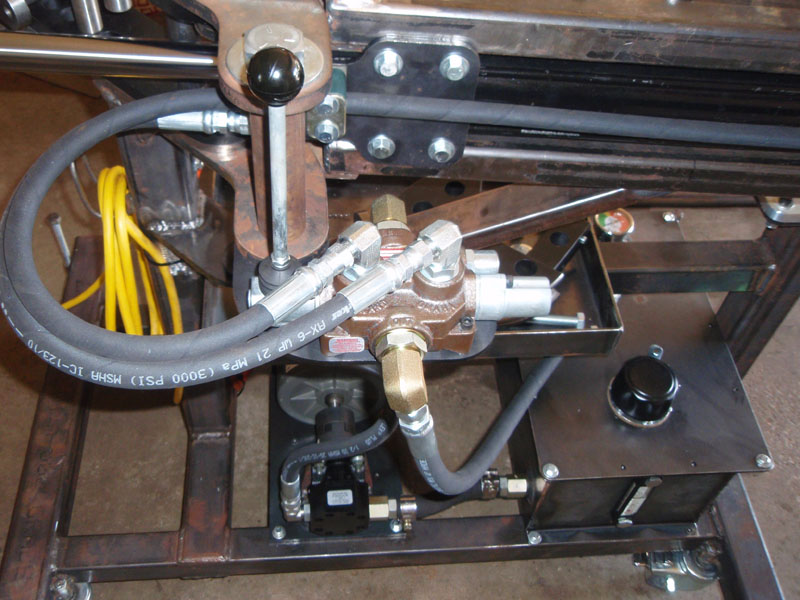

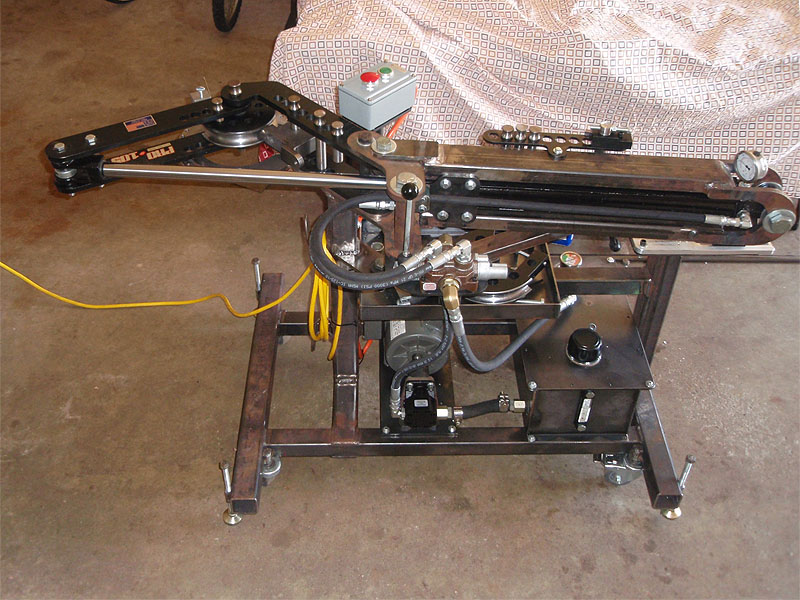

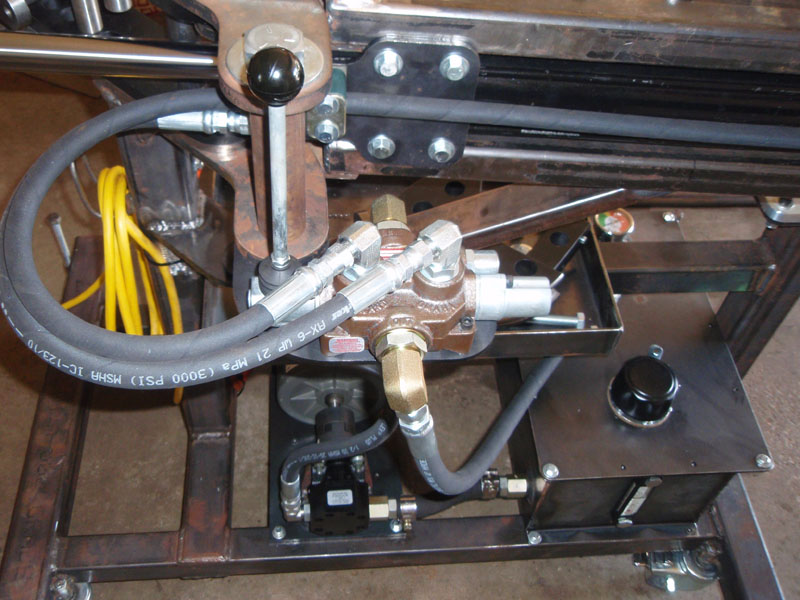

I built this last year. I spent a lot of time doing the math and researching hydraulic systems and benders to make sure everything I used would work well together and give me the speed and power I wanted. It's probably overkill for what I need but I enjoyed building it and doing the research. It's a different design than any of the other hyrdo benders I've seen in that the the cylinder starts at 90 degrees to the bender swing arm and pivots as is extends. This gives maximum power right from the start the of bend and not half way through it. Another unique thing is that it uses all SAE O-ring and JIC fittings for the hydraulics. This made finding the control valve, pressure gauge, in-tank filter, and tank bungs a little more difficult, but now I don't have to worry about leaks.

This thing is a beast. When bending 1-1/8" .120" wall tube it shows just a couple hundred PSI in the cylinder. If I did my math correctly this should have no problem bending 2" .135" wall chromoly. It will bend to over 100 degrees in one stroke in about 10 seconds.

Sorry the video sucks. This was filmed on my old crappy camera before I got my GoPro HD Hero.

Some pic's of the build process:

Parts drawn in CAD and laser cut

Laying out the base for the frame. Wish I had my welding table at the time.

Starting to look like something

Welding up the hydraulic oil tank.

Tray

Water testing the tank

95% complete, usable, and about how it looks now.

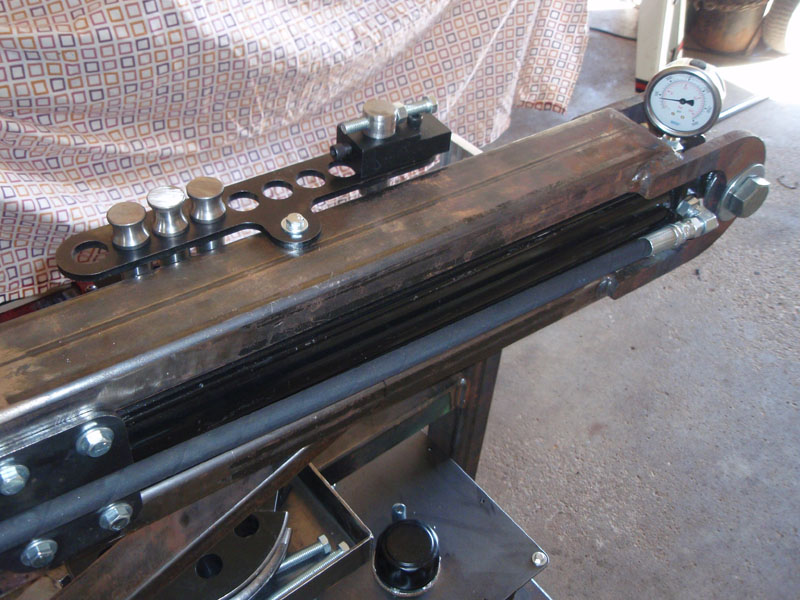

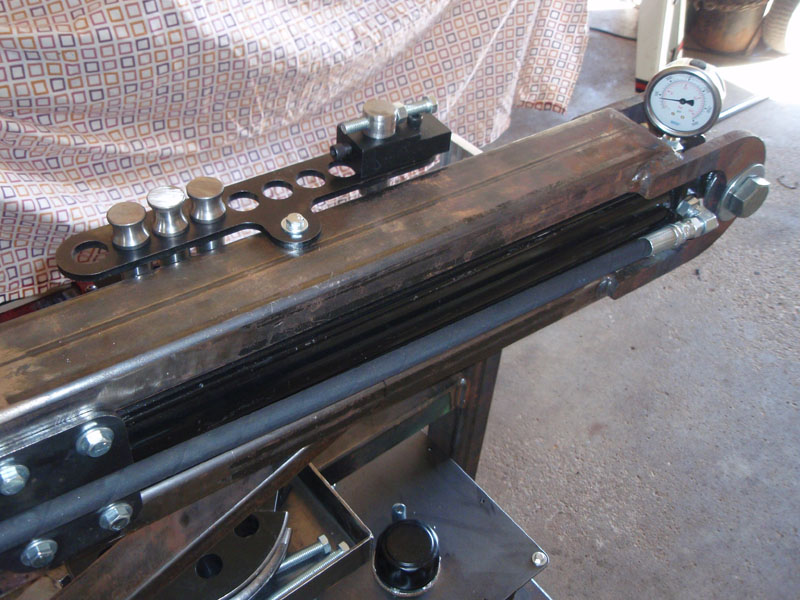

Piston rod extended

I built this last year. I spent a lot of time doing the math and researching hydraulic systems and benders to make sure everything I used would work well together and give me the speed and power I wanted. It's probably overkill for what I need but I enjoyed building it and doing the research. It's a different design than any of the other hyrdo benders I've seen in that the the cylinder starts at 90 degrees to the bender swing arm and pivots as is extends. This gives maximum power right from the start the of bend and not half way through it. Another unique thing is that it uses all SAE O-ring and JIC fittings for the hydraulics. This made finding the control valve, pressure gauge, in-tank filter, and tank bungs a little more difficult, but now I don't have to worry about leaks.

This thing is a beast. When bending 1-1/8" .120" wall tube it shows just a couple hundred PSI in the cylinder. If I did my math correctly this should have no problem bending 2" .135" wall chromoly. It will bend to over 100 degrees in one stroke in about 10 seconds.

Sorry the video sucks. This was filmed on my old crappy camera before I got my GoPro HD Hero.

Some pic's of the build process:

Parts drawn in CAD and laser cut

Laying out the base for the frame. Wish I had my welding table at the time.

Starting to look like something

Welding up the hydraulic oil tank.

Tray

Water testing the tank

95% complete, usable, and about how it looks now.

Piston rod extended

I'd probably be interested in some just for the bling factor.

I'd probably be interested in some just for the bling factor. Just kidding.

Just kidding.

Mule charges over 4bills for this set up

Mule charges over 4bills for this set up