Dean

XS400 Enthusiast

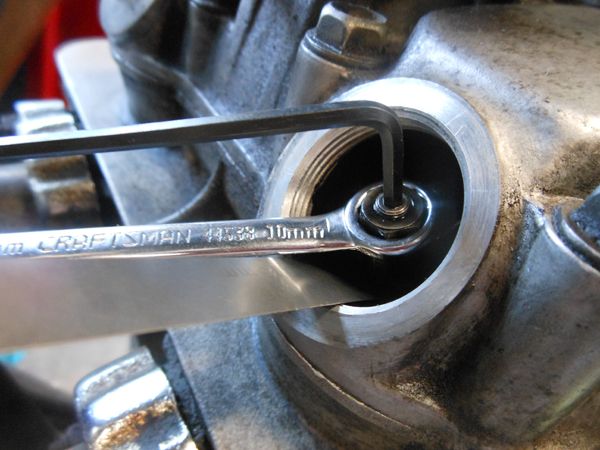

I drug home this hot little mess a couple of years ago. It's a '77 XS360, the basic entry level model with kick start only and drum brakes front and rear. The PO was up front about the fact that what's not missing doesn't work anyway and the exact volume of oil you pour in would be puddled on the ground within 15 minutes . It had a title so I traded him an old DVD player for it.

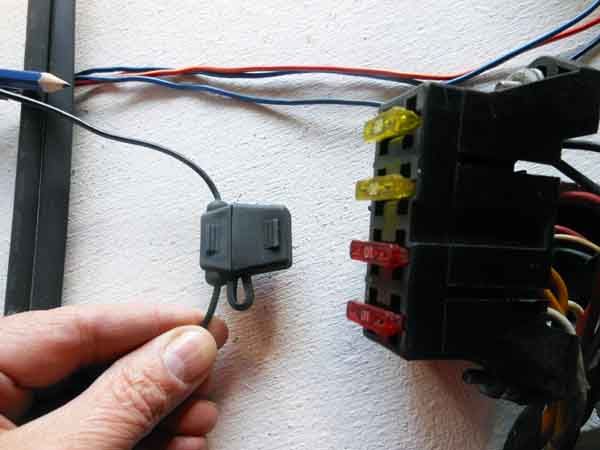

Other than the seat being torn up, the rotted mis-matched tires, rusty spokes, frayed clutch cable, broken brake cable , missing brake lever, busted switch gear, leaky forks, missing indicators, busted up pilot light console, vandalized ignition switch, shitty bumblebee spray bomb, wonky kickstand , a 30 amp bullet fuse spliced into each and every circuit , cheap ass emgo filter pods, dead battery, rusty jardine 2 into 1 pipe, toasted headlight etc. etc. etc. .... it's in pretty good shape for my next project.

This is a bare bones budget rescue using only the change in my couch and whatever is lying around my mess of a garage. It will make a fine Sheeple inspired Brat replica ;D

Here are some "before" photos:

oh, I'm a New Member, here is my intro :

http://www.xs400.com/forum/showthread.php?p=142358#post142358

Other than the seat being torn up, the rotted mis-matched tires, rusty spokes, frayed clutch cable, broken brake cable , missing brake lever, busted switch gear, leaky forks, missing indicators, busted up pilot light console, vandalized ignition switch, shitty bumblebee spray bomb, wonky kickstand , a 30 amp bullet fuse spliced into each and every circuit , cheap ass emgo filter pods, dead battery, rusty jardine 2 into 1 pipe, toasted headlight etc. etc. etc. .... it's in pretty good shape for my next project.

This is a bare bones budget rescue using only the change in my couch and whatever is lying around my mess of a garage. It will make a fine Sheeple inspired Brat replica ;D

Here are some "before" photos:

oh, I'm a New Member, here is my intro :

http://www.xs400.com/forum/showthread.php?p=142358#post142358

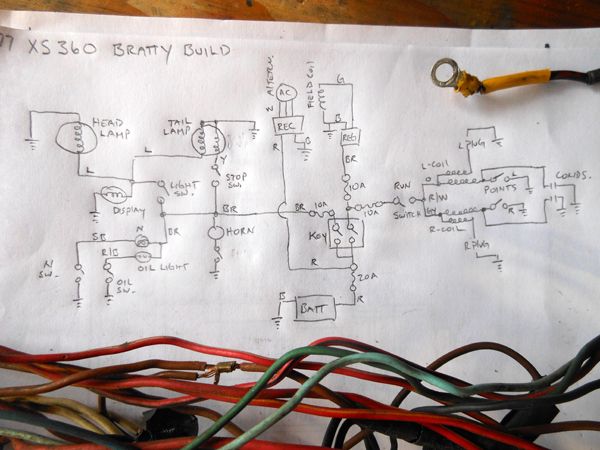

I'll clean all this up when I go through the wiring

I'll clean all this up when I go through the wiring