FUBAR

XS400 Addict

I finally got 5 minutes time to look at the bike and snap some pictures, can anyone clear up what exactly i have?

i think is a SOHC 81 400 special..?

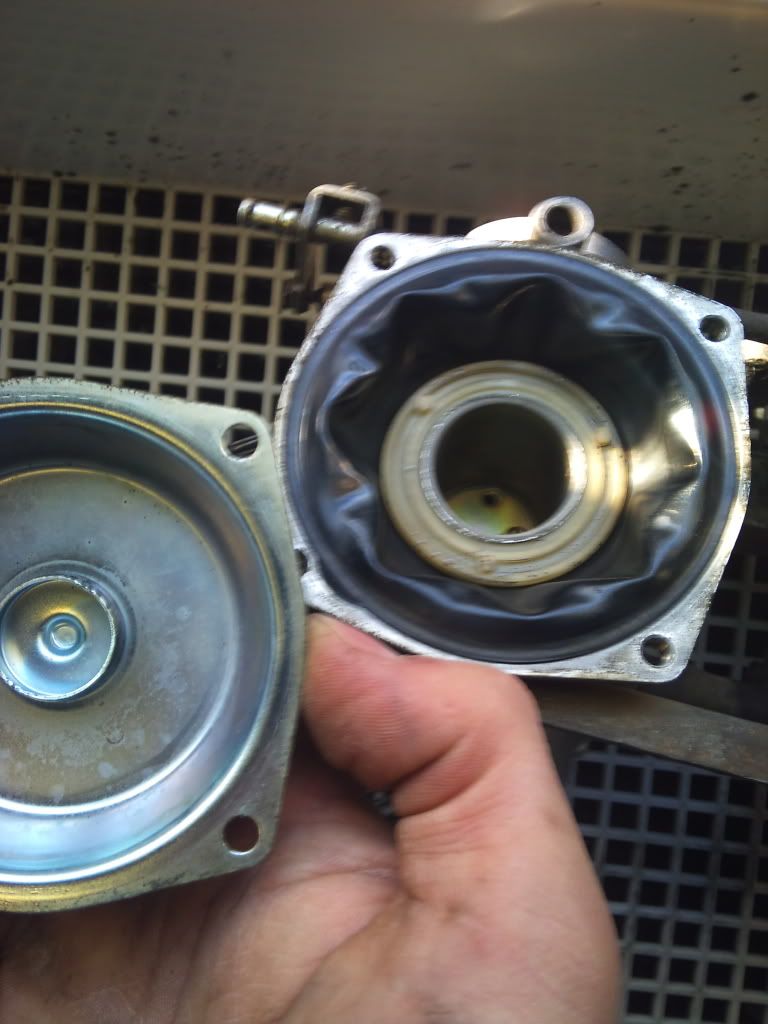

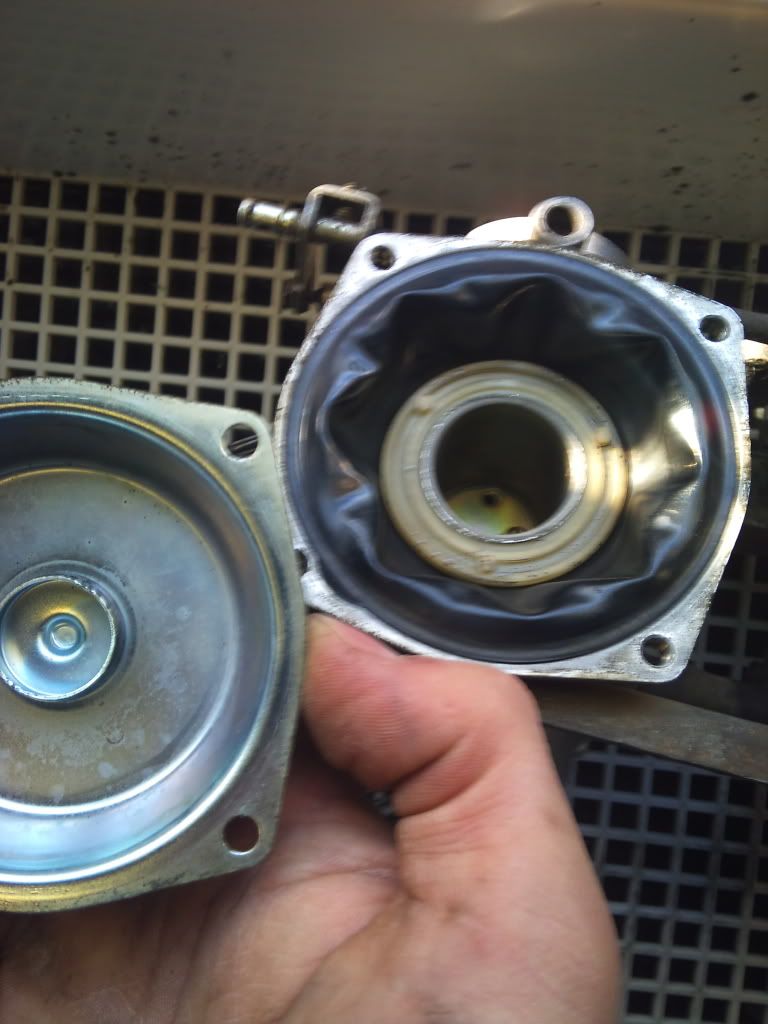

i also ripped apart the carbs and it looked to me like either someone recently changed out the diaphrams and cleaned everything up or it was well cared for in the past.

i also got a 2nd engine with the purchase but im not sure what plans the PO had with it.. im not sure if the one in the frame is a runner but i assume so, these jap engines can go though hell. it reads 20000 KM on the odom. i need to pick up a deep socket to pull the plugs and check compressn.

shifted through all gears easily and is nice and firm on the kickstart. thoughts?

i think is a SOHC 81 400 special..?

i also ripped apart the carbs and it looked to me like either someone recently changed out the diaphrams and cleaned everything up or it was well cared for in the past.

i also got a 2nd engine with the purchase but im not sure what plans the PO had with it.. im not sure if the one in the frame is a runner but i assume so, these jap engines can go though hell. it reads 20000 KM on the odom. i need to pick up a deep socket to pull the plugs and check compressn.

shifted through all gears easily and is nice and firm on the kickstart. thoughts?