I checked the inside of my fuse block and found this -probably off a Suzuki dirtbike or something. Hmmm , strange colors.

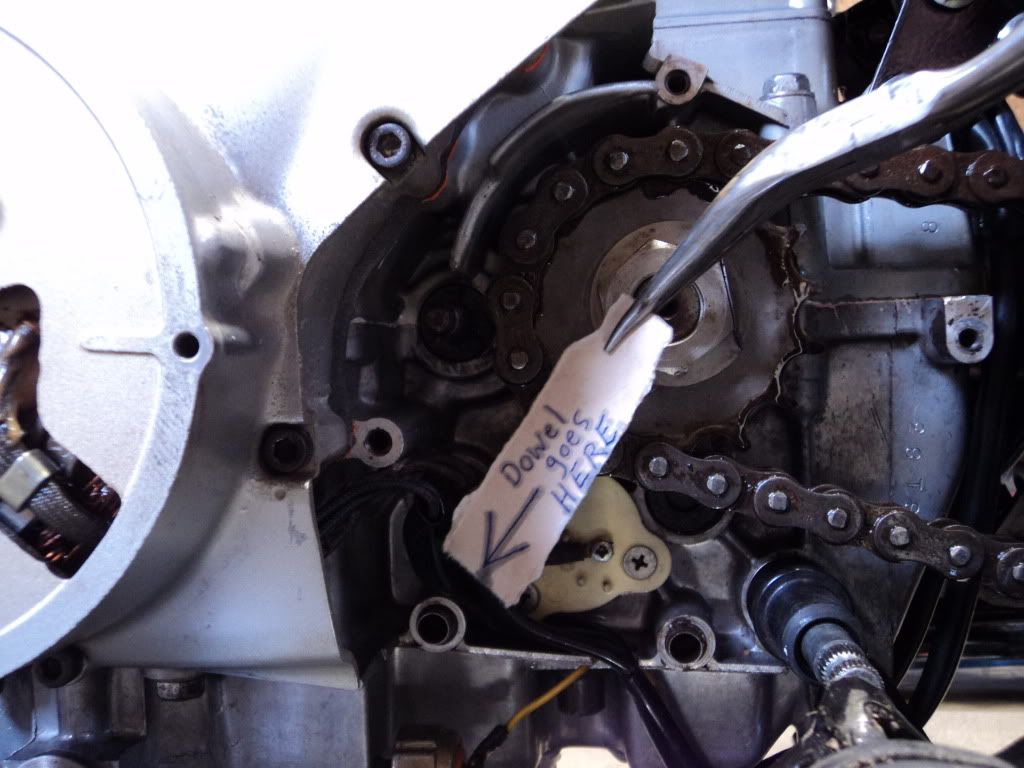

Even worse I actually bothered to zip-tie it back on and then shortly after discovered THIS!

The 2 red mains were hand-twisted and not fused. The fuse box has a black which is plated to all the fuses. The Headlight (B/Y), Signal (Br), and Ignition (R/W) from one side of the connector were hand tied together into that black.

Then from fuse box a White/Green to signal, a B/R to headlights, a B/Br to Ignition and a Br/L for nowhere (no need for a fuse there! and all fuses were 15 amp).

So I cut the fuse box off, crimped insulated slide connectors on and to the appropriate fuses - and this is a temporary solution

- but my question is. . is it that simple or am i overlooking something. If that simple then why the elaborate confusing effort the PO messed with??

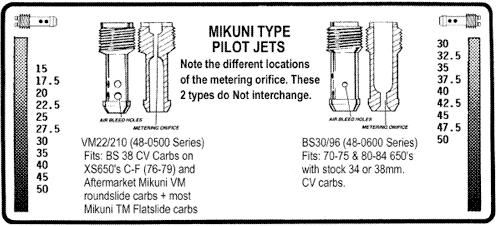

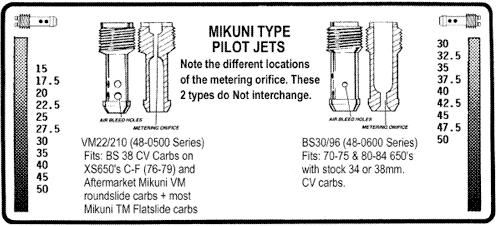

Conclusion so far: signals, indicators, brake/taillight are good. Getting ignition spark good. I don't know yet about headlights et. al because floats are set wrong and also I ordered the correct size main jet and the CORRECT PILOT JET, on the way in the mail from MikesXS (not SCI). Finally decided to order them as I should have to begin with because. . .

Even worse I actually bothered to zip-tie it back on and then shortly after discovered THIS!

The 2 red mains were hand-twisted and not fused. The fuse box has a black which is plated to all the fuses. The Headlight (B/Y), Signal (Br), and Ignition (R/W) from one side of the connector were hand tied together into that black.

Then from fuse box a White/Green to signal, a B/R to headlights, a B/Br to Ignition and a Br/L for nowhere (no need for a fuse there! and all fuses were 15 amp).

So I cut the fuse box off, crimped insulated slide connectors on and to the appropriate fuses - and this is a temporary solution

- but my question is. . is it that simple or am i overlooking something. If that simple then why the elaborate confusing effort the PO messed with??

Conclusion so far: signals, indicators, brake/taillight are good. Getting ignition spark good. I don't know yet about headlights et. al because floats are set wrong and also I ordered the correct size main jet and the CORRECT PILOT JET, on the way in the mail from MikesXS (not SCI). Finally decided to order them as I should have to begin with because. . .

).

).

I like fire but not that much fire!

I like fire but not that much fire!