Hey,

So I finally had some time in-between studying for exams, so I did some work on the old motor.I also got my Gasket set so im excited

.

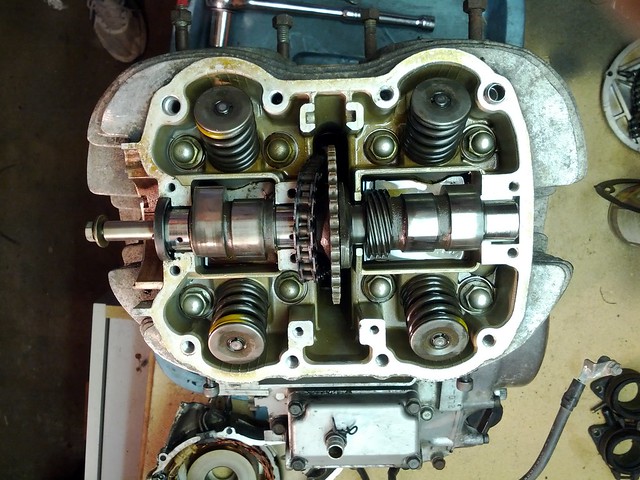

Wow did that ever take a lot of work to get the timing chain off! My motor would not rotate 360 because of crap on the Cylinders The cylinders were hitting the valves stoping rotation. This stopped me from being able to get at the second bolt off from overhead cam sprocket.

I was able to grind down one a wrench so i could fit it in between the sprocket and carefully unbolt it. Im lucky nothing got striped. The cam pulls out really easily once the timing chain is off.

Support the timing Chain so it does not disappear into the abyss. I later swapped out the screwdriver and used a 'cut up' coat hanger.

The head came off fairly easily. I just grabbed ahold of it firmly and rocked it back and fourth with my hands.To my relief the cylinders rotated 360 freely once the head was off, but this is what I found.

A bee trying hard to turn into fossil fuel.

I sprayed bunch of cleaner-degreaser onto the piston heads and then used a shop vac to clean them while there were still in the cylinders. I had just gone to the dentist so I was inspired by the tooth cleaning, I try and use my shop vac all the time to keep things clean and dry along the way.

So the next step was to remove the cylinder head. This was tricky I should have lubed up the cylinders and rotated the pistons up and down in the cylinders before removal, because I found the top end really tricky to pull off. To pull off the top I just pulled and pulled on the top end. Perhaps this is a good thing they were had to remove does this mean the piston rings are still good?

I used lots of support around the pistons to stop them from damaging themselves while I pulled the top off.

Is it ok that the gunk is below the first ring? The bike did sit for 5 years?

Towels off looks clean below

I really hope I dont have to replace the piston rings what do you think?

@haga41cat

@ThePsuedoMonkey thanks for the info, I think im going to try Soda Blasting.

@tritowns thats cool I cant find anything about motor burial, wish I could find out more about that.

@ Drewcifer "paint thinner, you'll be vaporizing a flammable substance " Good point I think I will stay away from that. I could make a cool flame thrower

@drewpy

@Liamthedevastator Do you mean $10/hr? I am in vic, I have heard of the DIY sandblasting. I think im going to try Soda blasting the motor because im cheep and like DIY things. But Perhaps ill sand blast my gas tank and frame.

Here is my other project.