cabbott12321

1977 XS360

So before I start soldering things and what not I had a few questions and wanted to make sure I had everything I needed. Not I haven't soldered or anything lack that, just have everything basically laid out before I make any moves.

Here is simply everything I have.

I ran 3 white wires through the top grommet and due lack of colors, two green through the bottom.

Here it is on the other side and where one of my questions comes up, on Drewpy's write up he said that the fourth wire is redundant and just had one wire run into the grommet and terminate there. So here I have it set up to have three of the white wires connect and then I need to run the fourth wire just into the grommet right?

Then on the bottom I have my two green wires to connect (underneath eventually) to the blackish and dark greenish wires, which seems pretty simple.

Then the three white wires go into this terminal which will go into the terminal on the bike that has three white wires coming out of it right?

And the two greens will go into the dark greenish and blackish ones here that go into the terminal with a bunch of colors in it, which I don't know off the top of my head and can't check at the moment. Which brings me to another question, with this bunch of wires from this terminal there'll be a yellow and blue wire right (or at least there used to be, i'll probably have to use different colors)? and I'm pretty sure I know where the yellow is supposed to go because I left it attached down at the bottom of the bike, it looks like a ground or something but I have absolutely no clue what the blue wire is or where it goes i just know it goes to the same terminal as these wires.

I still need to buy some pvc tubbing but I found some rubber insulating tape stuff that I didn't know if I'd use but tell me what you guys think.

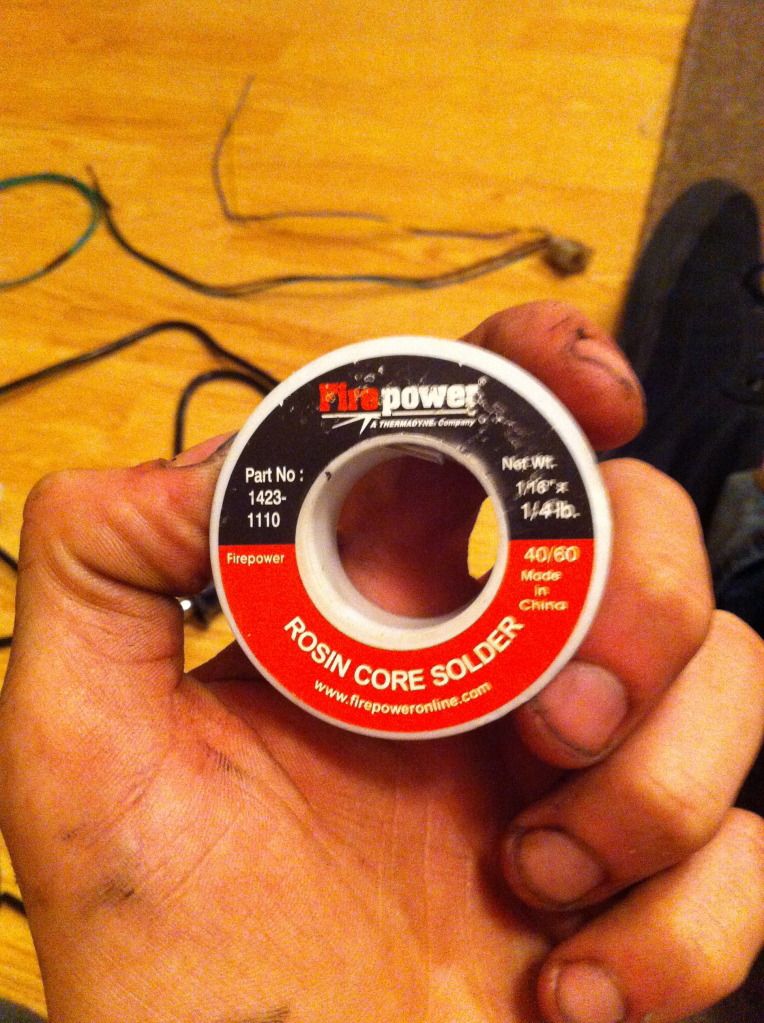

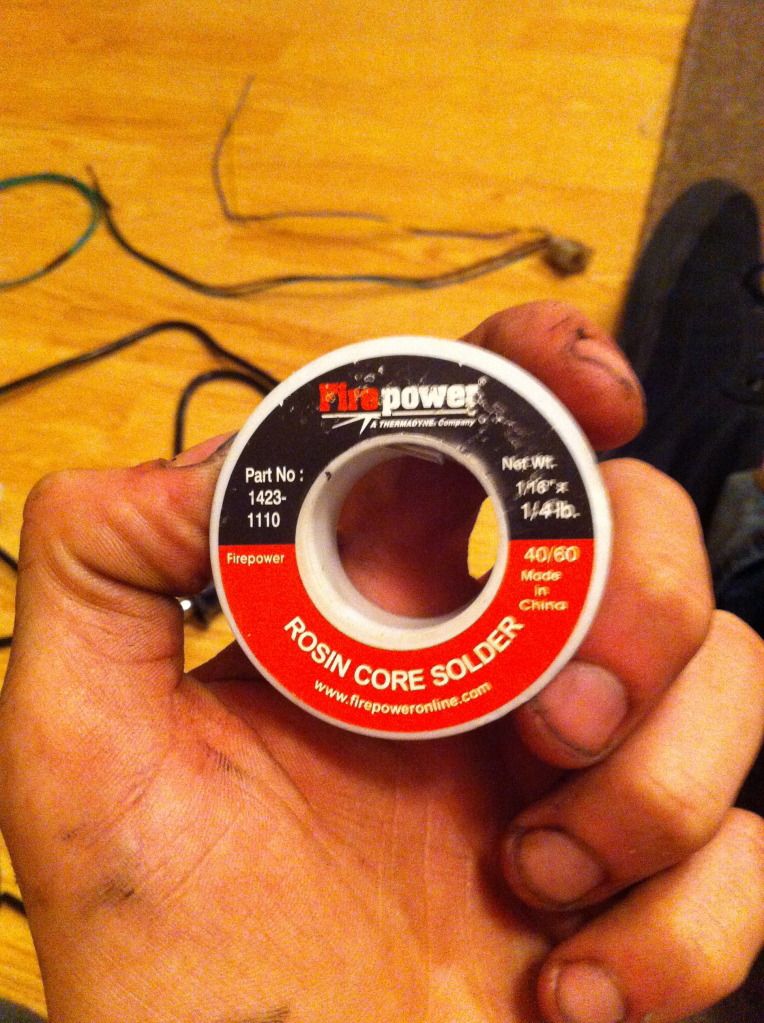

This is the solder I have, I don't know if its the right stuff or not.

So what else do I need to buy/need to do? I'm sure I'm missing something, just need some help here! Thanks!

Thanks!

Here is simply everything I have.

I ran 3 white wires through the top grommet and due lack of colors, two green through the bottom.

Here it is on the other side and where one of my questions comes up, on Drewpy's write up he said that the fourth wire is redundant and just had one wire run into the grommet and terminate there. So here I have it set up to have three of the white wires connect and then I need to run the fourth wire just into the grommet right?

Then on the bottom I have my two green wires to connect (underneath eventually) to the blackish and dark greenish wires, which seems pretty simple.

Then the three white wires go into this terminal which will go into the terminal on the bike that has three white wires coming out of it right?

And the two greens will go into the dark greenish and blackish ones here that go into the terminal with a bunch of colors in it, which I don't know off the top of my head and can't check at the moment. Which brings me to another question, with this bunch of wires from this terminal there'll be a yellow and blue wire right (or at least there used to be, i'll probably have to use different colors)? and I'm pretty sure I know where the yellow is supposed to go because I left it attached down at the bottom of the bike, it looks like a ground or something but I have absolutely no clue what the blue wire is or where it goes i just know it goes to the same terminal as these wires.

I still need to buy some pvc tubbing but I found some rubber insulating tape stuff that I didn't know if I'd use but tell me what you guys think.

This is the solder I have, I don't know if its the right stuff or not.

So what else do I need to buy/need to do? I'm sure I'm missing something, just need some help here!

Thanks!

Thanks!