Today i finished carbs!

thanks xschris, the float height is set to 26mm, i checked float needles, they are all metal.

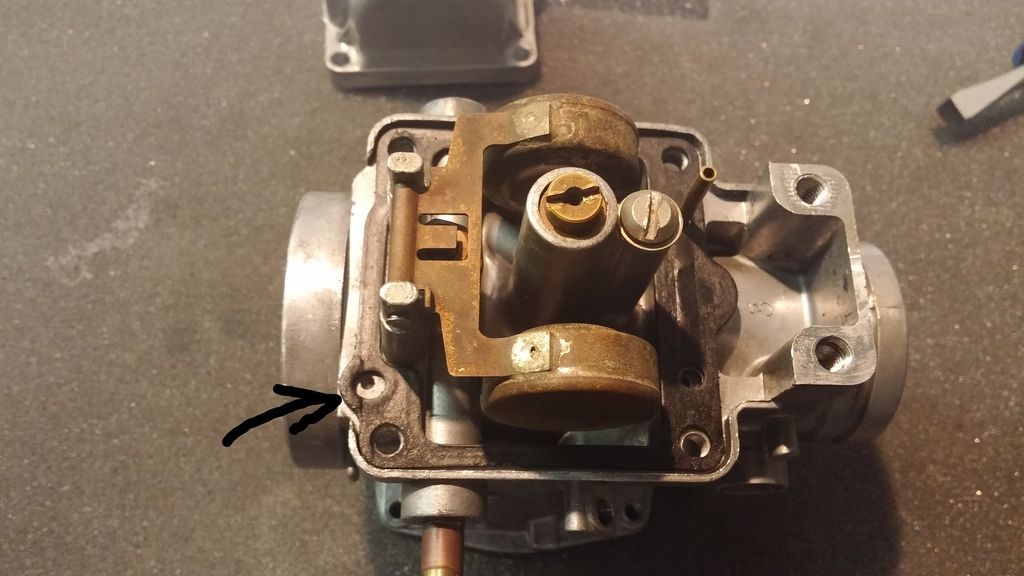

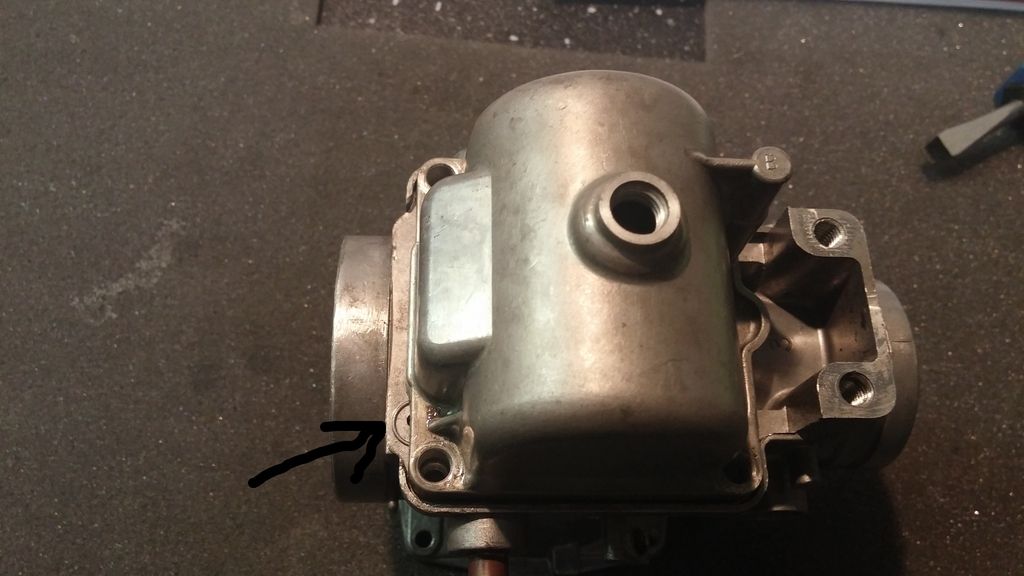

Here they are, they dont look the best, but they look way better than before.

what was done:

- dissasembled and cleaned in ultrasonic cleaner

- sprayed with carbcleaner, rubbed with silicone brush

- all jets and small parts cleaned with carb cleaner and inspected

- all important passages sprayed and checked

- changed shaft seals

- floats set to 26mm

- changed all screws

- bench synced

cannot check if they work because bike is not ready to be started, so i have to wait if the cleaning and rebuilding was succesfull. lets hope it was

As you can see on the picture, I am missing choke shaft knob, any hints for replacement? searched ebay but no luck. I saw some funny knobs made from dice, or small 8ball. Or should i made something on my own? any hints?

next to do:

- change fuse box to blade type (ordered)

- check all electrical components and eliminate faulty parts