Robj

XS400 Enthusiast

I Started a rebuild thread  http://www.xs400.com/forum/showthread.php?t=7411

http://www.xs400.com/forum/showthread.php?t=7411

Hi,

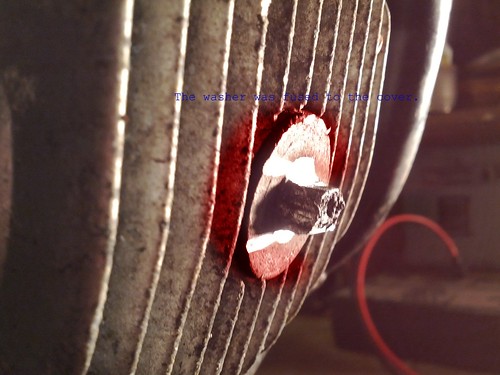

I have decided to pull the motor off my 79 xs and restore the bike.I have been fighting a striped oil filter case bolt for several hours now with the bolt winning. I used a monkey wrench with no luck. So then I decided to drill it then use a screw extractor on it the first size did nothing but strip the small hole so I drilled a bigger hole, big enough for the next size extractor I put the extractor in and it broke off in the hole.. So frustrating were do I go next, heat, drill again or weld. I have heard cobolt drill-bits can drill out the Hardend Steel of the extractors but they are expensive. Perhaps its worth renting a welding torch. How will I ever get this bolt out and worse the motor wont come out unless the bolt s out of the way and why is it so stuck...

So frustrating were do I go next, heat, drill again or weld. I have heard cobolt drill-bits can drill out the Hardend Steel of the extractors but they are expensive. Perhaps its worth renting a welding torch. How will I ever get this bolt out and worse the motor wont come out unless the bolt s out of the way and why is it so stuck...  (Yes I have been torquing counter clockwise).

(Yes I have been torquing counter clockwise).

.

BAD.

.

WORSE.

Hi,

I have decided to pull the motor off my 79 xs and restore the bike.I have been fighting a striped oil filter case bolt for several hours now with the bolt winning. I used a monkey wrench with no luck. So then I decided to drill it then use a screw extractor on it the first size did nothing but strip the small hole so I drilled a bigger hole, big enough for the next size extractor I put the extractor in and it broke off in the hole..

So frustrating were do I go next, heat, drill again or weld. I have heard cobolt drill-bits can drill out the Hardend Steel of the extractors but they are expensive. Perhaps its worth renting a welding torch. How will I ever get this bolt out and worse the motor wont come out unless the bolt s out of the way and why is it so stuck...

So frustrating were do I go next, heat, drill again or weld. I have heard cobolt drill-bits can drill out the Hardend Steel of the extractors but they are expensive. Perhaps its worth renting a welding torch. How will I ever get this bolt out and worse the motor wont come out unless the bolt s out of the way and why is it so stuck... .

BAD.

.

WORSE.

Last edited: