an update:

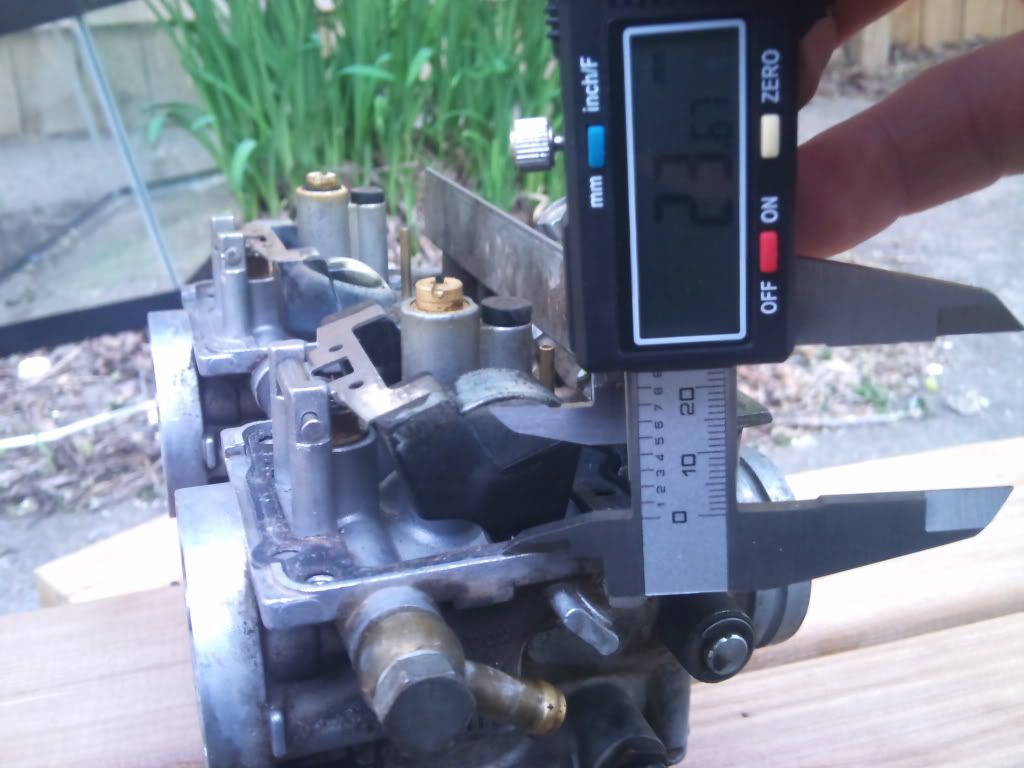

and i know its listed a few places on here but as for float level the book says 32mm, drewpy says 26mm im going to do 26, but how is the carb oriented when measuring?

carb upside down, float resting on tang. gasket off measure from where gasket was to (the now) top of the float

im still not sure i set the float height correct, before i touched anything it was at 16mm from where the gasket sits to the lower ridge on the edge of the float like the hanyes manual says, i took off the float assy. and bent the tang with a flat head to set it to 26mm, this seems like quite alot of bend.. so much that the tang doesnt line up with the spring well anymore and there is no movement up or down in the float assy. if that makes sense. can some one tell me what the heck i did wrong. heres some pictures of one side adjusted to 26ish and the other left alone.

im still not sure i set the float height correct, before i touched anything it was at 16mm from where the gasket sits to the lower ridge on the edge of the float like the hanyes manual says, i took off the float assy. and bent the tang with a flat head to set it to 26mm, this seems like quite alot of bend.. so much that the tang doesnt line up with the spring well anymore and there is no movement up or down in the float assy. if that makes sense. can some one tell me what the heck i did wrong. heres some pictures of one side adjusted to 26ish and the other left alone.

Got my hard tail kit from Travis last week, havent had a chance to get it welded up but i have a couple jig ideas to get everything perfectly true.

Got my hard tail kit from Travis last week, havent had a chance to get it welded up but i have a couple jig ideas to get everything perfectly true.